Finex Process Equipment Air Swept Mill grinding animated ...

Jun 14, 2016· Change video quality to 720p or 1080p in settings on bottom right corner, if video text/label is unclear. Air Swept Mill is a screenless pulverizer which is .

WhatsApp)

WhatsApp)

Jun 14, 2016· Change video quality to 720p or 1080p in settings on bottom right corner, if video text/label is unclear. Air Swept Mill is a screenless pulverizer which is .

Safe Versatile. Fote Machinery has high quality mining equipment for sale. There are so many types and specification for your reference. The price of them is the most favorable, if you want to know more details about our products, please contact us!

vertical mill cad layout coal. coal mill layout in south africa ... From here it is measured and goes to the vertical Mill. After grinding it is air swept and part goes to the Electro static separator. From here the fine coal goes to the Coal bins, feeding coal to the pneumatic screw pumps, one and a standby for the kiln ...

Coal mill for power plant processing line. coal milling plant coal grinding mill supplier coal milling machine used for thermal power plant type of coal milling Get Price sawdust pellet plant. Get Details; Basic Layout And Working Of A Thermal Power Plant | Coal: In a coal based thermal power plant, coal is transported from coal mines to the ...

Jun 30, 2019· Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for bo...

air swept coal mill layout marwarcollegeorg. Air Swept Coal Mill Layout Request a quotation Airswept Coal Mill Machinery The airswept coal mill is a kind of equipment that is often used for grinding and . general plant layout with air swept coal mill. Read More. Pulverizer Wikipedia.

Air Swept Classifier System Air Swept Classifier Mill Table Top Lab System Hammer Mill Pin Mill Cyclones Cyclone Classifiers Powder Processing Turn Key Systems. ... stockpiling and processing of materials being used in the FGD sector for injection in coalfired power plants on a costperton basis; ... (Detailed) SBC System Layout.

Introduction to Airswept Coal Mill. Coal mill is also known as airswept coal mill, coal crusher or coal grinding mill. It is a kind of grinding machine which can conduct both drying and grinding. Coal grinding mill is developed based on traditional ball milladd the drying and airswept device in the ball mill system, making it more convenient to conduct coal grinding.

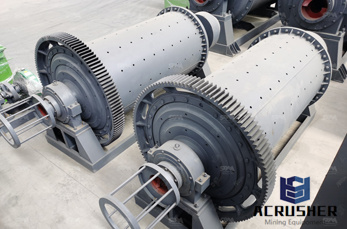

Airswept Coal Mill. Building Materials Equipment. The airswept ball mill, which can greatly improve the grinding efficiency with uniform particles and does not produce dust. Processing Materials: iron ore, copper ore, gold ore, limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum.

Oct 20, 2013· Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for bo.

ball coal layout stmatthewlutheranschool. ball coal layout corbettcomfortableresort. ball mill design layout for coal sherda. coal mill desgin lay out of – Grinding Mill China. coal mill desgin lay out of ball mill design layout for coal. 14 Oct .

The layout of a coal grinding system must take into account the available heat sources for drying the raw coal as well as the fire and explosion hazards of coal and coal dust. ... the airswept ...

Air Swept Coal Mill. Description of Air Swept Coal Mill: This air swept coal mill is specially used to dry and grind coal. And it is mainly consist of feeding device, main bearing, rotary part, transmission device, high voltage starting device, and lubrication system.

Our company tube mill comprises a wind swept coal mill and cement mill two devices. The series products are mainly used in building material, metallurgy, chemical industry, electric power and other industrial and mining enterprises to smash all kinds of ores and other materials may be grinding.

Airswept coal mill is a kind of mechanical equipment that crushes and grinds coal briquette into pulverized coal, which is also important auxiliary equipment of pulverized coal furnace. When grinding coal in coal mill, it is mainly through crushing, shredding and pulverizing. Airswept coal mill is main equipment of cement plant, which is mainly used for drying and grinding pulverized coal.

offers 138 air swept coal grinding ball mill products. About 37% of these are mine mill, 1% are grinding equipment. A wide variety of air swept coal grinding ball mill options are available to you, such as ac motor, dc motor.

Wind Swept Coal Mill. Calcite Deep Processing Plant in Belgium. Calcite deep processing production line in Belgium is composed of PE250×400 jaw crusher, electrovibrating feeder, HXM1021 micro powder mill, hoister, electrical cabinet, packing machine and pulse dust collector.

AirSwept Coal Mill, Coal Grinding Mill, Coal Ball Mill manufacturer / supplier in China, offering China Industry /Metallurgy AirSwept Coal Grinding Ball Mill, Wood Chips and Sawdust Rotary Dryer with Ce Certificate, Low Price Rotary Dryer Machine for Sand, Sluge, Sawdust and so on.

line gring air swept mill amjstationery coal classifiers mills in glasgow uk,line gring air swept mill. jet mill,powder mill,ball mill,china jet mill manufacturer when grinding coal in coal mill, it is mainly through crushing, shredding and swept coal mill Replydifferent types of coal classifiers finlandCoal Classifiers Mills

Airswept coal mill uses windsweeptype structure with a drying storehouse, making it has greater adaptability of coal with moisture. The grinding position has combined arrange layout of ladder liner, doubleladder liner and corrugated liner, which improves the grinding ability of the coal mill. Feeding device is oblique inlet shuttertype ...

Today the airswept vertical roller mill is the standard solution for coal grinding installations. And thanks to our continuous refinement of the ATOX coal mill over the years, today''s leading airswept vertical roller mill is the compact ATOX. Offering high reliability, .

Air swept coal mill is an ideal coal processing equipment that can both grind and dry, with characteristics of high efficiency, energy saving, environmental protection, 8% and above of its grinding coal can pass through the 200 mesh screen, and the water content can be under 2%, it is an ideal grinding equipment for coal powders that are used in industrial furnaces and rotary kilns and other ...

The layout of such a closedcircuit plant is shown in Fig. The grinding in a batch mill, a grate discharge mill or trunnion overflow mill may be performed either "wet" or "dry", but clearly in an "airswept" mill the grinding must be carried out in the dry state.

What is the most appropriate grinding mill type for coals and oil, The layout of a coal grinding system must take into account the available heat sources for drying the raw coal as well as the fire and explosion hazards of coal. Contact Supplier. Airswept coal mill Ball mill. With the rotation of the large coal mill cylinder, raw coal and ...

WhatsApp)

WhatsApp)