IRON ORE PELLET PLANT BALLING DISC IMPORTANT PART .

Dec 07, 2017· IRON ORE PELLET PLANT BALLING DISC IMPORTANT PART FunZone. Loading... Unsubscribe from FunZone? ... Pelletization of iron ore Duration: 4:06. Ministry of Steel 4,033 views.

WhatsApp)

WhatsApp)

Dec 07, 2017· IRON ORE PELLET PLANT BALLING DISC IMPORTANT PART FunZone. Loading... Unsubscribe from FunZone? ... Pelletization of iron ore Duration: 4:06. Ministry of Steel 4,033 views.

Iron ore pelletizing plant Métal 7. Metal 7 designs and manufactures highly advanced roller screens, disc filters ... Metal 7 can also analyze and optimize the iron ore pelletizing process in order ... exit of the balling drums or discs, depending on the technology used at the plant.

iron ore pellet plant manufacturer/supplier, China iron ore pellet plant manufacturer factory list, find qualified Chinese iron ore pellet plant manufacturers, suppliers, factories, exporters wholesalers quickly on

The iron ore and additives with given moisture content are pelletized (formed into small balls referred to as green balls or green pellets) in a balling device. This could be a balling drum or a balling disk Pellets of various sizes exiting the balling device are discharged afterward on a deck of rollers, the roller screen, for removal of the ...

Balling Disc For Iron Ore Pellets pizzeriatavernet. disc balling machine for ore beneficiation plant Process Flow DIagram Brmani River Pellets Limited Low grade iron ore fines 57% Fe are subjected to Beneficiation process to The iron ore fines of mm size from the stockpile is conveyed to Beneficiation plant for Bentonite is used as a binder for proper balling of the filter cake particles ...

Zhengzhou Mega Industry Co., Ltd., Experts in Manufacturing and Exporting mining machinery,ball mill and 489 more Products. A Verified CN Gold Supplier on

Outotec Traveling Grate Pelletizing is the industry''s leading induration technology for iron ore pellet processing and is designed for a wide range of plant capacities up to million t/a. Based on over 60 years'' experience and worldclass RD, our process produces uniform pellets with excellent physical and metallurgical properties.

for taconite ore processing is 303023. Table lists the SCCs for taconite ore processing. Taconite is a hard, banded, lowgrade ore, and is the predominant iron ore remaining in the United States. Ninetynine percent of the crude iron ore produced in the United States is taconite. If

Mar 21, 2015· Understanding Pellets and Pellet Plant Operations. Pelletizing is an agglomeration process which converts very fine grained iron ore into balls of a certain diameter range (normally 8mm to 20 mm, also known as pellets. These pellets are suitable for .

costs – the Traveling Grate process for plants with large capacities and the Steel Belt process for those with smaller ones. Pelletizing turns very fi negrained iron ore into balls of a certain diameter, also known as pellets, which are suitable for blast furnace and direct reduction. Pellet plants can be located

The iron ore concentrate is now mixed and ready for the pelletizing process. Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet .

Understanding Pellets And Pellet Plant Operations Ispatguru. Mar 21 2015 understanding pellets and pellet plant operations pelletizing is an agglomeration process which converts very fine grained iron ore into balls of a certain diameter range normally 8mm to 20 mm also known as pellets these pellets .

Exporter of Iron Ore Pellet Plants Disc Pelletizers, Rotary Kilns, Traveling Grates and Pellet Coolers offered by Varsha Techno Ind Equip Pvt. Ltd, Hyderabad, Telangana.

The idea of rolling moist fine ore in a drum to form balls and then drying and firing it was first ... Typical pellet plant using disc pelletizer as balling technology. ... Organic binders of iron ...

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter shows the status of the pelletizing process ...

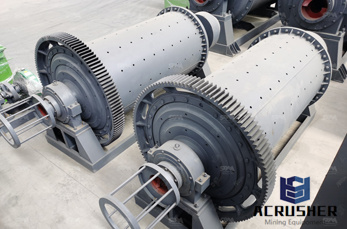

Ball Disk For Iron Ore Pellet Plant, Find Complete Details about Ball Disk For Iron Ore Pellet Plant,Ball Disc,Ball Disk,Pelletising Machine from Other Mining Machines Supplier or ManufacturerZhengzhou Mega Industry Co., Ltd.

Balling Disc In Pelletization Of Iron Ore Process. As a global leading manufacturer of products and services for the mining industry, our company can provide you with advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

pellets and plant equipment, as well as the cost of the plants. Lately, however, the environmental aspects of ... breeze (fuel). Pellets are made from iron ore that is finer than that used for sintered ore. The ore fine is formed into spheroids, called green balls, approximately ... reducing the amount of pellets returned. The disc

Iron ore pellets and Pelletizing processes. satyendra; February 23, 2013; 4 Comments ; Grate kiln process, Iron ore fines, iron ore pellets, Pelletization processes, Straight kiln process, Iron ore pellets and Pelletizing processes Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh with additives like bentonite and then ...

Table of ContentsDesign Considerations for Selecting a Grinding SystemOpen vs. Closed Circuit Dry GrindingEffect on Pellet QualityOperating Considerations Screening during the production of highgrade lump ore for blast furnace burden, particularly from recently developed ore deposits in Australia, South America, and Africa, has resulted in large tonnages of fine iron ore.

The low grade iron ore deposit of PurBanera Belt of Rajasthan has remained unexploited even though it was explored by Geological Survey of India, way back in the year 196970. Af

Balling Disc For Iron Ore Pellets disc balling machine for ore beneficiation plant. Process Flow DIagram Brmani River Pellets Limited. Low grade iron ore fines 57% Fe are subjected to Beneficiation process to The iron ore fines of mm size from the stockpile is conveyed to Beneficiation plant for Bentonite is used as a binder for proper balling of the filter cake ...

Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can be found in houses, cars and appliances.

Iron ore pelletizing plant – Métal 7. Métal 7 manufactures rotating disc filtration systems for . straight gatetype induration furnaces use layers of cured iron ore pellets .

WhatsApp)

WhatsApp)